Southern Trailer Works Showroom

2026 MacDon C2012C

Get in Touch

Description

2026 MacDon C2012C

C Series Corn Header

Corn headers may be a new product for MacDon, but understanding what's essential for harvesting performance isn't. MacDon is bringing over 75 years as The Harvesting Specialists into the cornfield, and delivering corn harvesting performance and innovation in true MacDon fashion.

Features May Include:

- Advantages

With a strong focus on corn agronomy, MacDon C Series headers provide industry-leading residue management thanks to our OctiRoll™ Residue Management System. In a one-pass process, our Corn Headers create well conditioned/chopped and evenly distributed residue, necessary for achieving accurate seed depth and seed placement essential for maximizing successive crop yields. - One-Pass Residue Management

With a strong focus on the agronomy of corn, MacDon C Series headers provide industry-leading residue management. In a one-pass process MacDon's OctiRoll™ Residue Management System creates well conditioned/chopped and evenly distributed residue, necessary for achieving accurate seed depth and seed placement essential for maximizing successive crop yields. - Crimping

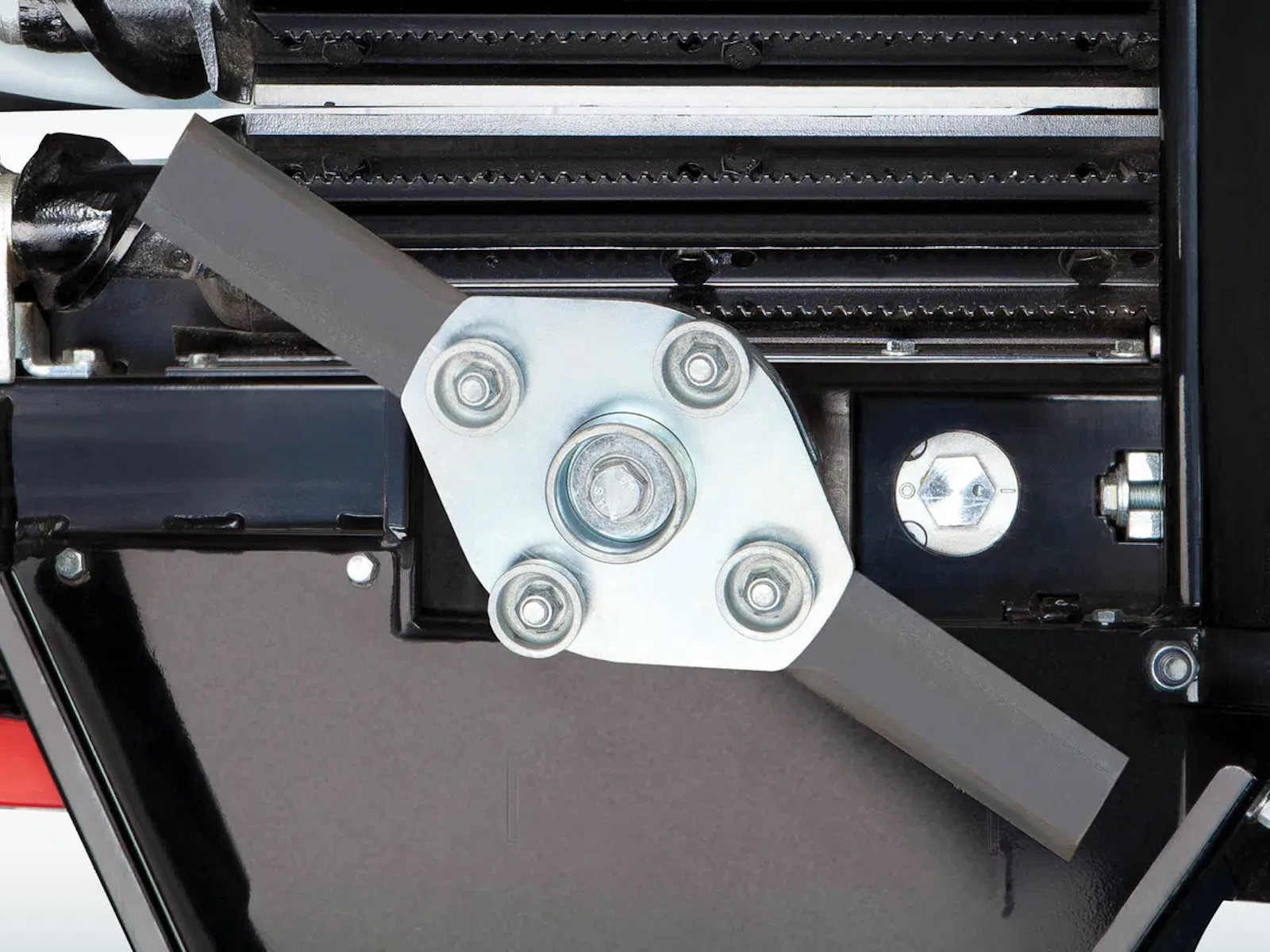

C Series Corn Headers feature MacDon's innovative OctiRoll™. Improving on the traditional snapping roll model, this unique industry-leading design incorporates 4 point-to-point knives and 4 serrated edges, that alternate to cut and crimp the stalk every 3 inches. The OctiRoll™ cutting/crimping action speeds up the microbial breakdown process, taking less than half the time to decompose over typical corn headers. - Chopping

Stalks are aggressively pulled through the header and residue is consistently chopped into 2 to 3-inch pieces at harvesting speeds up to 7.5 mph (12 km/h) thanks to the extra 4 serrated blades on each OctiRoll™. -

Optimal Stalk to Chopper Positioning

The front-mounted chopper positioned close to the underside of the rolls provides the shortest, most consistent residue size. The OctiRolls can then be run closer to the ground to better harvest downed corn while delivering the shortest stubble height possible.

You'll enjoy the direct positive drive from the specially designed high-capacity aluminum gearbox and slip clutch that powers each row unit. Chopper speed is 2800 RPM, and the chopper gearboxes can be easily disconnected row by row as needed. -

Unique Snout Design

The ribbed shape strengthens the snout structure and creates less drag allowing the material to flow over it smoothly. Featuring a unique teardrop snout design that excels at lifting downed crop, minimizing ear bounce, and following curved rows, the MacDon C Series is ready for your toughest corn harvesting challenges. -

More Advantages

Strong, light, and fuel-efficient, C Series headers have aluminum gearboxes and a compact driveline requiring less power from the combine for operation. Featuring a unique snout design that excels at lifting downed crop, minimizing ear bounce, and following curved rows, the MacDon C Series is ready for your toughest corn harvesting challenges. -

Strong, Light, and Fuel Efficient

A light yet robust frame structure and row units reduce weight.

The reduced frame weight, high-performance OctiRolls, aluminum gearboxes and compact driveline require less power from the combine resulting in reduced fuel consumption. -

Serious Cutting Performance & Innovation

MacDon's OctiRoll™ Residue Management System features 4 point-to-point knives and 4 additional serrated edges on each OctiRoll™. This feature creates more pinch points on the stalk per revolution of the roll, resulting in less trash intake, stalk slippage, and allows for a more thorough stalk cut, crimping, and chopping process.

Chopper models feature aluminum stalk chopper gearboxes with large oil volumes to help prevent overheating.

The optimized position of the chopping knives relative to the snapping rolls ensures excellent chopping quality

even at harvesting speeds up to 7.5 mph (12 km/h).

Knives can be reversed when the front edge wears to prolong life & reduce operational costs -

Easy Maintenance

Each front-supported OctiRoll™ uses two sealed double row ball bearings. The grease in the cavity forms a barrier to prevent dirt & debris from contacting the bearing seal. The greasing interval is weekly or every 50 hours of operation. -

Built Tough for Increased Harvesting Up-Time

The high-performance OctiRolls feature 4 hardened carbide knives bolted to each roll shaft for easy replacement.

The gathering chain drive sprockets feature a unique tooth profile that protects the gathering chain should the chain meet an obstruction; this also helps to protect the row unit driveline. -

Combine Interchangeability

MacDon C Series Headers are designed to fit most major brand combines with an easy to install completion package. This multi-brand compatibility and interchangeability mean your investment will hold its value when it's time to update your header. -

Features

Take your corn harvesting performance up a notch with MacDon performance options. Folding headers let you travel with ease from field-to-field during harvest. The rotary end divider option helps to lift downed crop, while stubble stompers help reduce tire or track wear. -

Folding Corn Headers

Folding headers let you travel with ease from field-to-field during harvest. Go from full width to completely folded in less than two minutes; the folding operates with push-button simplicity from the combine's cab. -

Colored Snouts & Dividers

Grey snouts and dividers are offered as standard equipment, however, red, green, and yellow are available as a special factory order to match your combine color. -

Rotary End Dividers

The rotary end divider option helps to pick up downed corn. -

Stubble Stompers

The stubble stomper option helps reduce wear and tear on your tires or tracks.

Info

Industry

Agriculture

Make

MacDon

Model

C2012C

Trim

Base

Year

2026

MSRP

N/A

Category

Header

Subcategory

Corn Head

Specs

Width

20 ft

Weight

7848 lbs